Product Features:

1. Main hydraulic components are selected from internationally renowned brands.

2. Drill head adopts a chuck type structure, with lateral translation function and three gear stepless

speed adjustment.

3. Drill head feeding adopts double-speed driving device for the chain of the oil tank.

4. Mast adopts oil cylinder lifting and lowering, foldable, convenient for transportation and storage,with sliding grounding function.

5. Hydraulic system adopts load sensitive control, and the rotation of drill head spindle is driven bydualmotor with closed loop hydraulic circuits, with high operation efficiency and high torque.

6. Mast is equipped with centering guide in its upper and lower part for inclined hole constructionconveniently. A hydraulic clamp is adopted at the position above the drilling hole.7.Equipped with two layer working platforms.

Model Numbers

Application

A core drilling rig is a professional equipment used to drill cylindrical rock cores/soil cores from geological formations such as rocks and soil. It can accurately obtain underground geological samples and is widely applied in scenarios like geological exploration, mineral survey, and engineering investigation.

Prices and pictures are for reference only. Actual quotes will be provided based on specific requirements. We have a professional technical and service team that strives to make everything perfect.

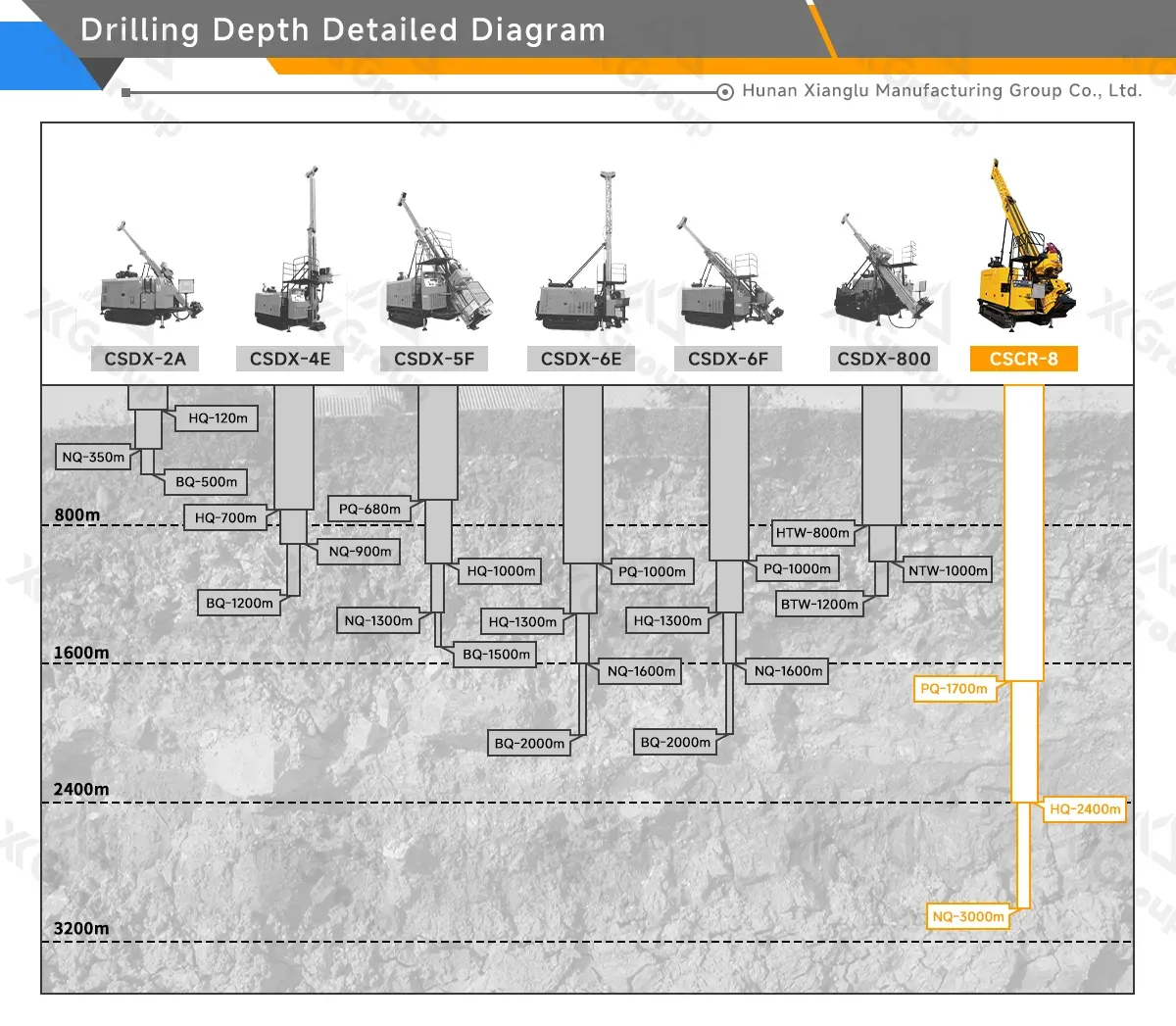

| Product Name | CSDX-2A | CSDX-4E | CSDX-5F | CSDX-6E | CSDX-6F | CSCR-8 | CSDX-800 |

| Drilling Capacity | BQ Drill Pipe: 500m, NQ Drill Pipe: 350m, HQ Drill Pipe: 120m | BQ Drill Pipe: 1200m, NQ Drill Pipe: 900m, HQ Drill Pipe: 700m | BQ Drill Pipe: 1500m, NQ Drill Pipe: 1300m, HQ Drill Pipe: 1000m, PQ Drill Pipe: 680m | BQ Drill Pipe: 2000m, NQ Drill Pipe: 1600m, HQ Drill Pipe: 1300m, PQ Drill Pipe: 1000m | BQ Drill Pipe: 2000m, NQ Drill Pipe: 1600m, HQ Drill Pipe: 1300m, PQ Drill Pipe: 1000m | NQ Drill Pipe: 3000m, HQ Drill Pipe: 2400m, PQ Drill Pipe: 1700m | BTW Drill Pipe: 1200m, NTW Drill Pipe: 1000m, HTW Drill Pipe: 800m, PQ Drill Pipe: 400m |

| Diesel Engine - Model | 4BTA3.9 - C100 | 6BTA5.9 - C180 | 6CTA8.3 - C215 (China III) | 6CTA8.3 - C270 (China III) | 6CTA8.3 - C270 (China III) | QSL8.9 - C360 | WP4.1NG175E301 |

| Diesel Engine - Rated Power (kW) | 74 | 132 | 160 | 240 | 240 | 264 | 129 |

| Diesel Engine - Rated Speed (r/min) | 2200 | 2200 | 2200 | 2200 | 2200 | 2100 | 2200 |

| Diesel Engine - Maximum Speed (r/min) | 1200 | 1150 | 1150 | 1150 | 1150 | 1100 | 1100 |

| Diesel Engine - Maximum Torque (N・m) | 900 | 5500 | 5900 | 6400 | 6400 | 8000 | 2400 |

| Power Head - Speed Range (r/min) | 405 - 874 (Gear I), 560 - 1200 (Gear II) | 105 - 206 (Gear I), 184 - 361 (Gear II), 334 - 656 (Gear III), 569 - 1150 (Gear IV) | 170 - 341 (Gear I), 539 - 1150 (Gear II) | 157 - 359 (Gear I), 509 - 1150 (Gear II) | 157 - 359 (Gear I), 509 - 1150 (Gear II) | 254 - 508 (Gear I), 448 - 897 (Gear II), 526 - 1100 (Gear III) | 318 - 618 (Gear I), 570 - 1100 (Gear II) |

| Power Head - Corresponding Torque (N・m) | 900 - 425 (Gear I), 630 - 293 (Gear II) | 5500 - 2853 (Gear I), 3168 - 1613 (Gear II), 1743 - 887 (Gear III), 900 - 495 (Gear IV) | 5900 - 2958 (Gear I), 1868 - 934 (Gear II) | 6400 - 2805 (Gear I), 1978 - 865 (Gear II) | 6400 - 2805 (Gear I), 1978 - 865 (Gear II) | 8000 - 3611 (Gear I), 4091 - 2046 (Gear II), 3486 - 1743 (Gear III) | 2400 - 1239 (Gear I), 1433 - 690 (Gear II) |

| Power Head - Spindle Through-Hole Diameter (mm) | 1024 - 521 | 1024 - 521 | 121 | 121 | 121 | 121 | 98 |

| Power Head - Translation Distance (mm) | 98 | 350 | 465 | 510 | 465 | 695 | 400 |

| Feed Mechanism - Feed Stroke (mm) | 1800 | 3500 | 3800 | 3800 | 3800 | 4700 | 3500 |

| Feed Mechanism - Maximum Pull-Out Force (kN) | 50 | 150 | 180 | 240 | 240 | 295 | 200 |

| Feed Mechanism - Maximum Feed Force (kN) | 25 | 60 | 90 | 120 | 120 | 152 | 100 |

| Mast - Total Height (m) | 6 | 9.2 | 9.8 | 10.8 | 10 | 14.7 | 8.4 |

| Mast - Adjustment Angle (°) | 0 - 90 | 0 - 90 | 0 - 45 | 0 - 45 | 0 - 45 | 0 - 45 | 0 - 90 |

| Mast - Drilling Angle (°) | 45 - 90 | 45 - 90 | 45 - 90 | 45 - 90 | 45 - 90 | 45 - 90 | 45 - 90 |

| Mast - Sliding Stroke (mm) | 715 | 1100 | 1100 | 1100 | 1100 | 1100 | 725 |

| Rope Winch - Wire Rope Length (m) | 500 | 1000 | 1800 | 1800 | 1800 | 2500 | 1000 |

| Rope Winch - Wire Rope Diameter (mm) | 6 | 6 | 6 | 6 | 6 | 8 | 6 |

| Mud Pump - Model | BW - 100 | BW - 160 | BW - 250 | BW - 250 | BW - 250 | BW - 320 | BW - 160 |

| Mud Pump - Maximum Flow Rate (L/min) | 100 | 160 | 250 | 250 | 250 | 320 | 160 |

| Mud Pump - Maximum Pressure (MPa) | 1 | 10 | 6 | 6 | 6 | 10 | 10 |

| Orifice Holder - Through Hole (mm) | Φ124 | Φ154 | Φ154 | Φ154 | Φ154 | Φ154 | Φ154 |

| Crawler Chassis - Travel Speed (km/h) | 1.5 - 2.5 | 1.5 - 2.5 | 1.5 - 2.5 | 1.5 - 2.5 | 1.5 - 2.5 | 1.5 - 2.5 | 1.5 - 2.5 |

| Crawler Chassis - Gradeability (°) | ≤30 | ≤20 | ≤30 | ≤30 | ≤30 | ≤30 | ≤30 |

| Overall Dimensions - Working Dimensions (mm) | 4100×1840×6000 | 4800×2420×9200 | 4715×2240×9800 | 4635×2240×10820 | 4800×2220×10000 | 6020×2475×14745 | 4600×2000×8400 |

| Weight (Host) (t) | 5.5 | 9 | 13 | 13.5 | 13.5 | 25 | 9.5 |