Product Features:

1. The mechanical top drive power head is used to realize the functional integration of mud drilling and pneumatic

down-the-hole hammer drilling.

2. Drilling can only be performed at 90°.3. The driling rig adopts a long-stroke double-speed feeding mechanism and a mechanical power head, and the powerhead stroke reaches 2300mm. lmprove driling efficiency and reduce the occurrence of dril blockage and dril burning

accidents.4. The double oil pump is used for oil supply, and the hydraulic system uses the split-flow confluence technology. A singlepump is used for driling, and a double pump is used for confluence when lifting and lowering the drill, with less power lossand short auxiliary time.

5. The main shaft of the driling rig adopts mechanical transmission. The transmission efficiency is doubled, the powerenergy consumption is greatly reduced, and it is more efficient and energy-saving.

Model Numbers

Application

A core drilling rig is a professional equipment used to drill cylindrical rock cores/soil cores from geological formations such as rocks and soil. It can accurately obtain underground geological samples and is widely applied in scenarios like geological exploration, mineral survey, and engineering investigation.

Prices and pictures are for reference only. Actual quotes will be provided based on specific requirements. We have a professional technical and service team that strives to make everything perfect.

Click to play video

| Model/Item | Unit | CSDQ280 | XCSDQ280 | CSDQ350 | XCSDQ350 | CSDQ5 | XCSDQ5 |

| Weight | kg | 3800 | 4800 | 6000 | 7000 | 11000 | 12000 |

| Dimension (Transport) | mm | 4600*1900*2540 | 5600*1900*2600 | 6300*2000*2600 | 6300*2000*2600 | 6300*2000*2650 | 6300*2000*2800 |

| Dimension (Working) | mm | 3800*2200*5700 | 3800*2300*7000 | 3800*2400*7600 | 3800*2400*7600 | 3800*3250*8500 | 4200*3600*8800 |

| Drilling Angle | ° | 90 | 75-90 | 90 | 75-90 | 90 | 75-90 |

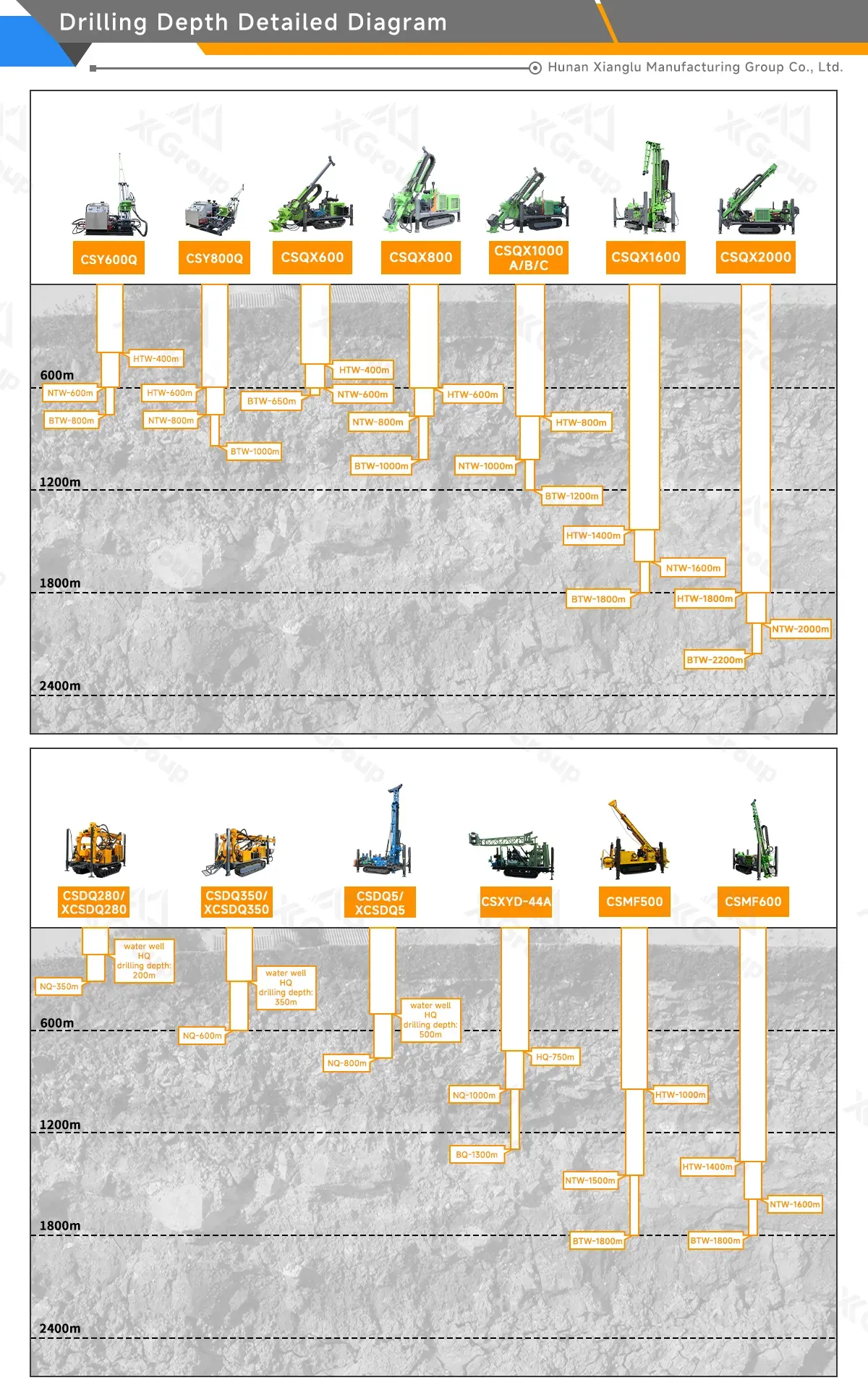

| Drilling Depth For Water Well | m | 200 | 200 | 350 | 350 | 500 | 500 |

| Wireline Coring N Size | m | 350 | 350 | 600 | 600 | 800 | 800 |

| Borehole (Drill bit) Dia | mm | Φ75-220 | Φ75-220 | Φ75-220 | Φ75-220 | Φ75-220 | Φ75-220 |

| Drill Head Lifting Force | kN | 100 | 100 | 120 | 120 | 240 | 240 |

| Drill Head Feeding Force | kN | 50 | 50 | 85 | 85 | 180 | 180 |

| Rotary Speed | rpm | Forward: 33-1120 Reverse: 37-180 | Forward: 33-1120 Reverse: 37-180 | Forward: 27-901 Reverse: 48-219 | Forward: 27-901 Reverse: 48-219 | Forward: 43-1080 Reverse: 47-144 | Forward: 43-1080 Reverse: 47-144 |

| Max. Torque | N.m | 9800 | 9800 | 10500 | 10500 | 12000 | 12000 |

| Drill Head Feed Stroke | mm | 2300 | 2500 | 3500 | 3500 | 3500 | 3500 |

| Drill Pipe Dia | mm | Φ60、Φ76、Φ89 NQ/HQ/BQ | Φ60、Φ76、Φ89 NQ/HQ/BQ | Φ60、Φ76、Φ89 NQ/HQ/BQ | Φ60、Φ76、Φ89 NQ/HQ/BQ | Φ60、Φ76、Φ89 NQ/HQ/BQ | Φ60、Φ76、Φ89、Φ102 NQ/HQ/BQ |

| Engine Model | / | Yunnei YN27 | Yunnei YN27GBZ | Yunnei YNG27 | Yunnei YN27GBZ | Yunnei YN48GBZ | Yunnei YN48GBZ |

| Rated Power | kw | 42 | 58 | 58 | 65 | 92 | 92 |

| Rated Speed | rpm | 2400 | 2400 | 2400 | 2400 | 2400 | 2400 |

| Walking Speed | km/h | 0-2 | 0-2 | 0-2 | 0-2 | 0-2 | 0-2 |

| Climbing Angle | ° | 25-30 | 25-30 | 25-30 | 25-30 | 20 | 20 |

| Mechanical Winch Capacity | kN | 30 | 30 | 45 | 45 | 80 | 80 |

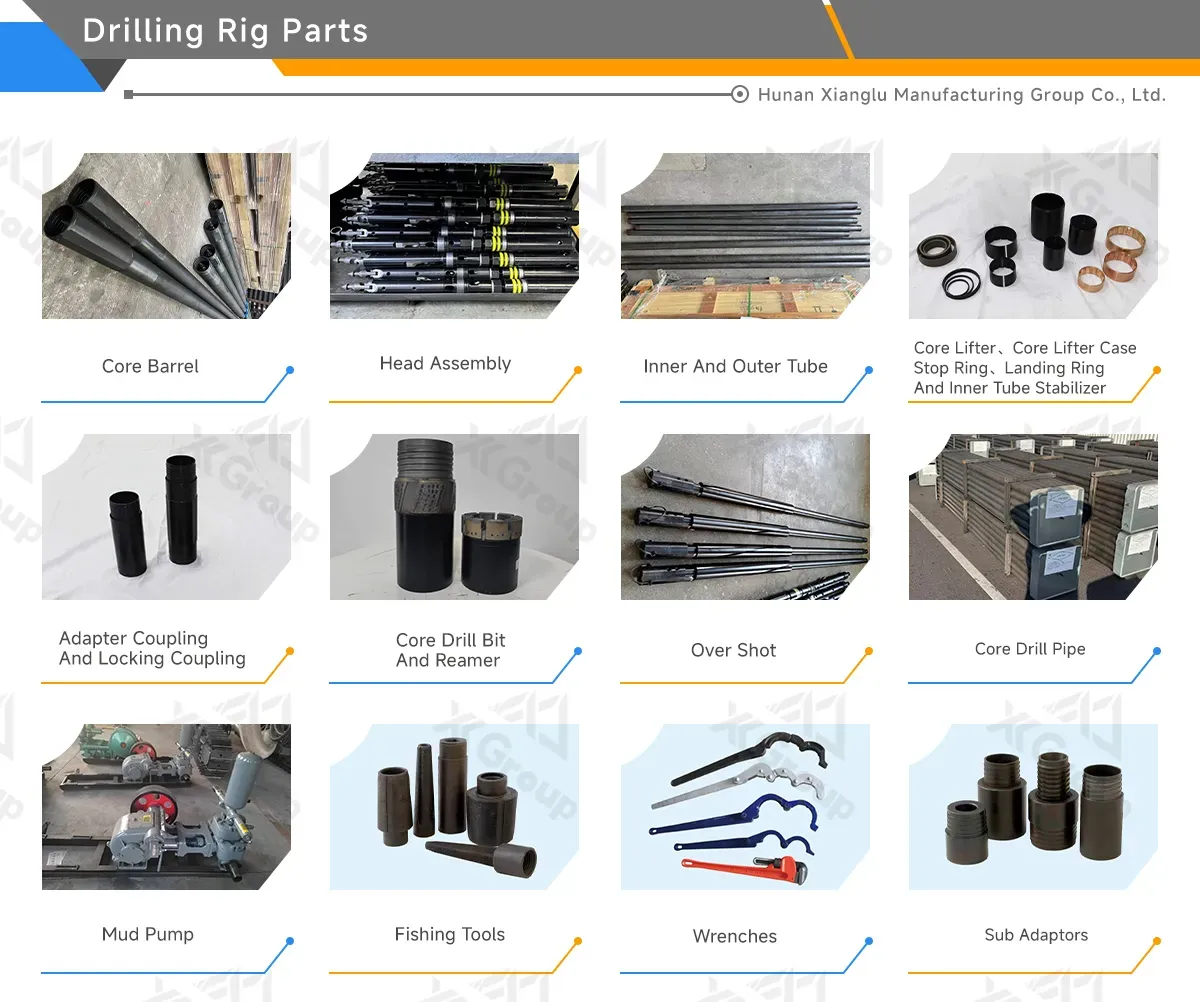

| Mud Pump | / | BW160/BW200/BW250 (Optional) | BW160/BW200/BW250 (Optional) | BW160/BW200/BW250 (Optional) | BW160/BW200/BW250 (Optional) | BW160/BW200/BW250 (Optional) | BW160/BW200/BW250 (Optional) |

| Crawler Chassis | / | Rubber 350mm*56 | Steel 300mm*38 | Rubber 300mm*38 | Rubber 400mm*40 | Steel 400mm*43 | Steel 400mm*43 |

| Crawler Load | kg | 5000 | 6000 | 6000 | 8000 | 12000 | 12000 |